A LOOK TO THE FUTURE

Without question, future produce supply chains will function differently than today. Solutions to current and pending issues will come from selective adoption of technological innovations.

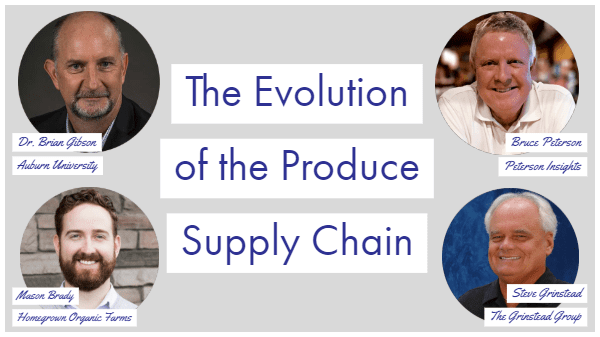

Our roundtable discussion participants are Mason Brady, director of finance and supply chain at Homegrown Organic Farms in Porterville, CA, which grows and markets certified organic blueberries, citrus, stone fruit, and grapes; Steve Grinstead, CEO of the Grinstead Group in Dallas, TX, which provides professional services to the food industry; and Bruce Peterson, president and founder of Peterson Insights in Bentonville, AR, which specializes in food merchandising and procurement consulting services.

Going forward, how can companies tame supply chain complexity?

Grinstead: I’m a big fan of technology. My companies were early adopters and I think technology will play a bigger role going forward.

Technology helps with everything from projecting your crops to planning your harvest to managing your freight and distribution centers. Performance expectations are higher for having product in stock where and when it’s needed for meeting delivery times. And, stiff consequences are levied if you don’t meet those expectations. You need technology to help you succeed.

Peterson: Technology is normally developed to support what’s happening in an industry but we’re not likely to see major vendors introduce technology that handles the nuances of the fresh fruit and vegetable industry. Our industry will morph toward a CPG business model that fits the technology demands of major retailers.

Grinstead: I agree. As I talk to people who are implementing ERP or other support systems, I always say “buy the technology you think is closest to how you would like to do business, and then adapt your business model to that system.”

Brady: Technology is changing quickly, and it’ll be cheaper in two to three years. Look at what’s out there and decide if it really makes sense for your business. Don’t blindly follow industry trends. Ask, does it really have value for my supply chain?

What about automation?

Peterson: The labor situation isn’t going to resolve itself; we will need to pursue driverless trucks and field automation.

Brady: We find it necessary to be careful with automation. While it may make sense from a financial perspective, consider if it will replace workers on a permanent basis. If you’re only going to displace baggers for a three-month seasonal product, then you’re not likely to get those workers back for the rest of the year. They’ll go elsewhere because they want consistent work.

And, the automated equipment still has challenges. There are mechanical harvesters that we’ve found don’t work well with some varieties of our blueberries. You may also need to change plant spacing and varieties to work with robotic harvesters, which will take some time to implement.

Grinstead: There will be greater use of replenishment tools that calculate projected needs and lead times. This allows each buyer to manage more products because they’re not working through buyer sheets. But they also aren’t regularly reviewing what’s selling before making decisions.

Peterson: There will be more reliance on data analytics to make these types of programmed decisions. You make faster choices, but you may not be taking the time to learn all the different things you need know. This will lead to less experience and expertise in some of the decision-making processes.

Any thoughts on blockchain?

Grinstead: There are components of blockchain that are very good—they store massive quantities of data and learn as they go. But, with all these competing blockchain systems and networks out there, how will you effectively blend them? I don’t know the answer to that yet.

Peterson: Blockchain is the newest buzz-technology; but, how do you create a transparent supply chain, while also protecting that part of the supply chain from a security and confidentiality standpoint? How do you limit access to only those who need to see it?

Brady: We’re starting to see Walmart go beyond PTI and get involved with blockchain. Perhaps it is a solution to help us get to better traceability.