Technology use in the produce industry increases every year, but it hasn’t yet made a digital transformation like some industries.

Rao Mandava, chairman and president of Inteligistics, hopes to help lead this transformation. The company sells supply chain technology, and its clients include Driscoll’s, Del Monte, Dole, Church Brothers, Fresh Express, Taylor Farms and Walmart.

“I want to bring technology from the industries I’ve worked in, to the produce industry,” he said.

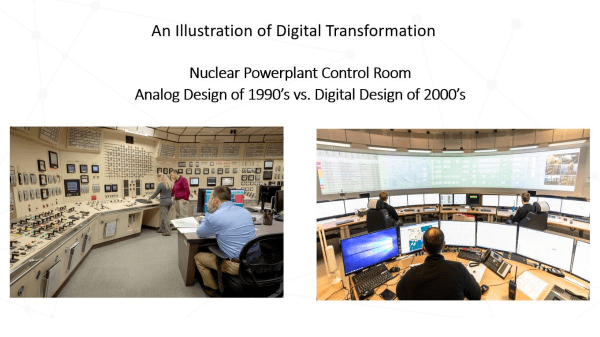

Those two industries are nuclear energy and airlines, and he thinks produce can learn from these examples.

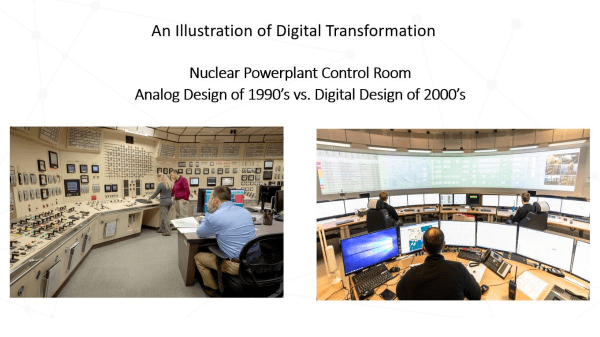

Before he started Inteligistics, Mandava used his mechanical engineering background first at Boeing and then at Westinghouse, where he managed a group that transformed the nuclear control room from analog to digital.

He said after it was done, the cost to operate a nuclear power plant dropped by two-thirds.

“It used little internet and no cloud, so we created our own network and artificial intelligence,” Mandava says. “We went from using over 10,000 cables to using about 100.”

He didn’t start a technology company specializing in fresh produce by chance. He was born into a farming family in India and has always had a passion for agriculture.

Inteligistics’ main products are InteliTemp, InteliCool, InteliMonitor and InteliDock, which all improve efficiency of existing systems using technology and analytics.

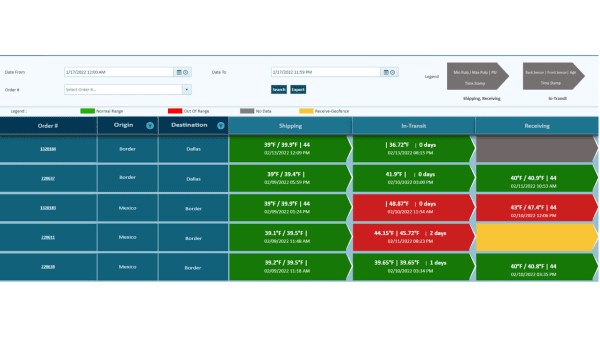

It’s dashboard product, InteliView, Mandava says, is one that could help lead the digital transformation.

“We can see what’s happening throughout the supply chain and correct problems when they arise,” he said.

One of the biggest challenges, he says, is that growers and retailers have to work together and use technology that works with each other, and that would mean each side would have to be more transparent.

One example, he says, is with product shelf-life. Growers can monitor product temperature throughout the supply chain and share that data, which can give retailers an ability to reduce shrink and costs and give consumers better products.

Inteligistics customers have to evaluate return on investment, of course, but Mandava says now it’s taking months rather than years. InteliView works with existing systems and products, he says.

“We work with other technology companies,” he says. “We know we can’t do it all ourselves or overnight.

He says the system also has food safety and sustainability data and eliminates information silos.

“It doesn’t have to be a big investment,” Mandava says. “Complete digitization can take less than a year.”